At the beginning of 2025, Webcontrol successfully installed an inspection rewinding machine and a slitting machine for a leading Japanese packaging manufacturer. Specializing in sustainable, recyclable, and versatile paper-based packaging materials, this customer serves industries such as food and beverage, consumer goods, pharmaceuticals, and industrial packaging.

Our long-term partner, Think Laboratory, played a crucial role in bridging this collaboration. With over 50 years of experience in flexible packaging solutions, Think Laboratory supplied their printing machine and introduced Webcontrol’s INSPECT-S Series inspection rewinding machine and SLIT-B Series slitting machine to enhance customer’s production capabilities. By integrating our high-performance equipment, we align with customer’s mission of sustainability, efficiency, and waste reduction.

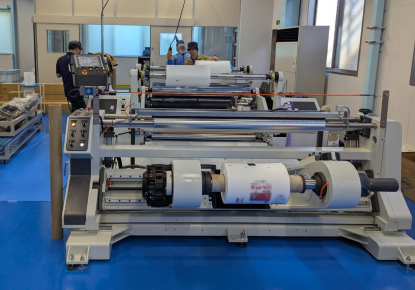

The INSPECT-S Series is engineered for efficiency, ease of operation, and superior quality control. Key features include:

- Hydraulic Lifting System & Clamp Device – Simplifies web loading/unloading and prevents slippage when changing rolls.

- S-Type Driven Guide Rollers – Ensures web stability and enables accurate defect detection via high-resolution cameras.

- Spread Rollers – Prevent wrinkles and enhance material quality.

- Automatic Tension Control System – Maintains proper web tension even at high speeds of 400m/min, ensuring smooth operation.

- Specially Treated Rollers – Prevent deformation when handling large paper rolls.

With these features, the INSPECT-S Series not only optimizes productivity and reduces manual labor but also ensures high-quality output with minimal material waste.

The SLIT-B Series is designed for high-precision paper roll slitting. Its advanced system ensures:

- Smooth Material Flow & Consistent Tension Control – From unwinding to rewinding, accommodating various paper grades and thicknesses.

- High-Precision Blades – Guarantees exact cuts with minimal deviation, reducing waste and producing uniform roll sizes for high-quality output.

- Additional Spread Roller – Prevents wrinkles and ensures perfect slitting results.

- Edge Trimming Collection System – Features an additional air shaft at the rewind side for efficient edge trim handling.

- Robust Construction & State-of-the-Art Control System – Delivers consistent, high-quality results tailored to customer’s specific production needs.

By implementing the SLIT-B Series, customer enhances its efficiency, precision, and waste reduction strategies, reinforcing its commitment to sustainable packaging.

We sincerely thank Think Laboratory for facilitating this successful partnership with this customer. We are confident that our INSPECT-S and SLIT-B Series machines will exceed expectations in terms of performance, reliability, and quality control.

Webcontrol looks forward to continued collaboration with this customer and Think Laboratory, contributing to innovative, sustainable, and high-performance packaging solutions for the global market.